Company Advantages1. Cleanmo sampling swabs uses the high-grade basic materials in complete compliance with industry standards. Cleanmo's cleanroom swabs are ideal for cleaning small areas, precision electronics, etc

2. Whether this product is meant for retail or is going to be used for shipping, it is more than just a way to protect the merchandise. It is the first impression of a brand. Cleanmo's cleanroom and ESD consumables are well recognized by clients like Seagate, Hitachi, and Sony

3. The product is hypo-allergenic. It contains few allergy-producing substances such as nickel, but not enough to cause irritation. Each handle of Cleanmo's cleanroom swabs is smooth on the surface

4. The product features chemical resistance. It can resist the effects of chemicals like acids, salts, and alkalis and won't easily swell or soften. More than 100 types of swabs are supplied under Cleanmo brand

5. The product has optimized air permeability. No matter its ventilated design nor its ultra-fiber materials are all adopted in this product to guarantee the dry environment. Cleanmo's cleaning kits are designed to keep the printers free of dust, dirt, lint and other debris

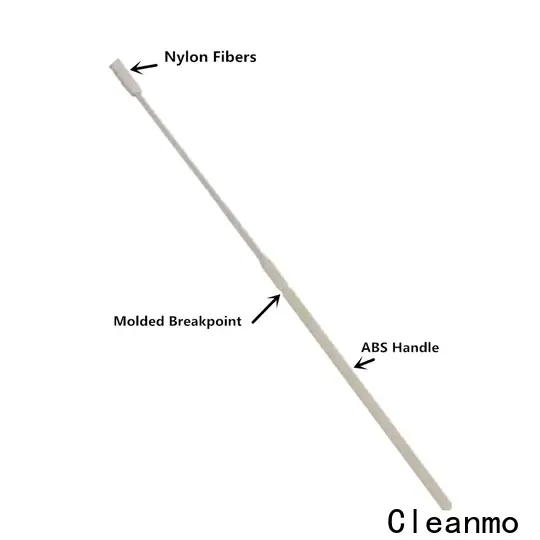

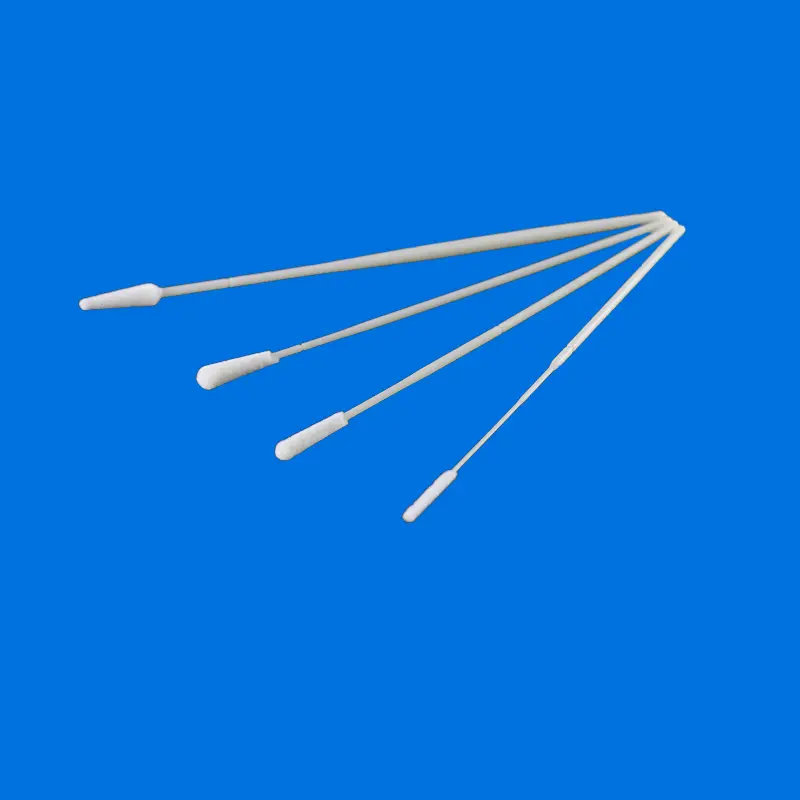

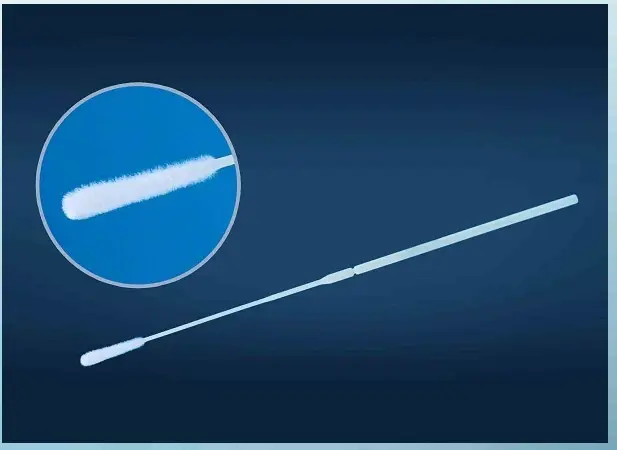

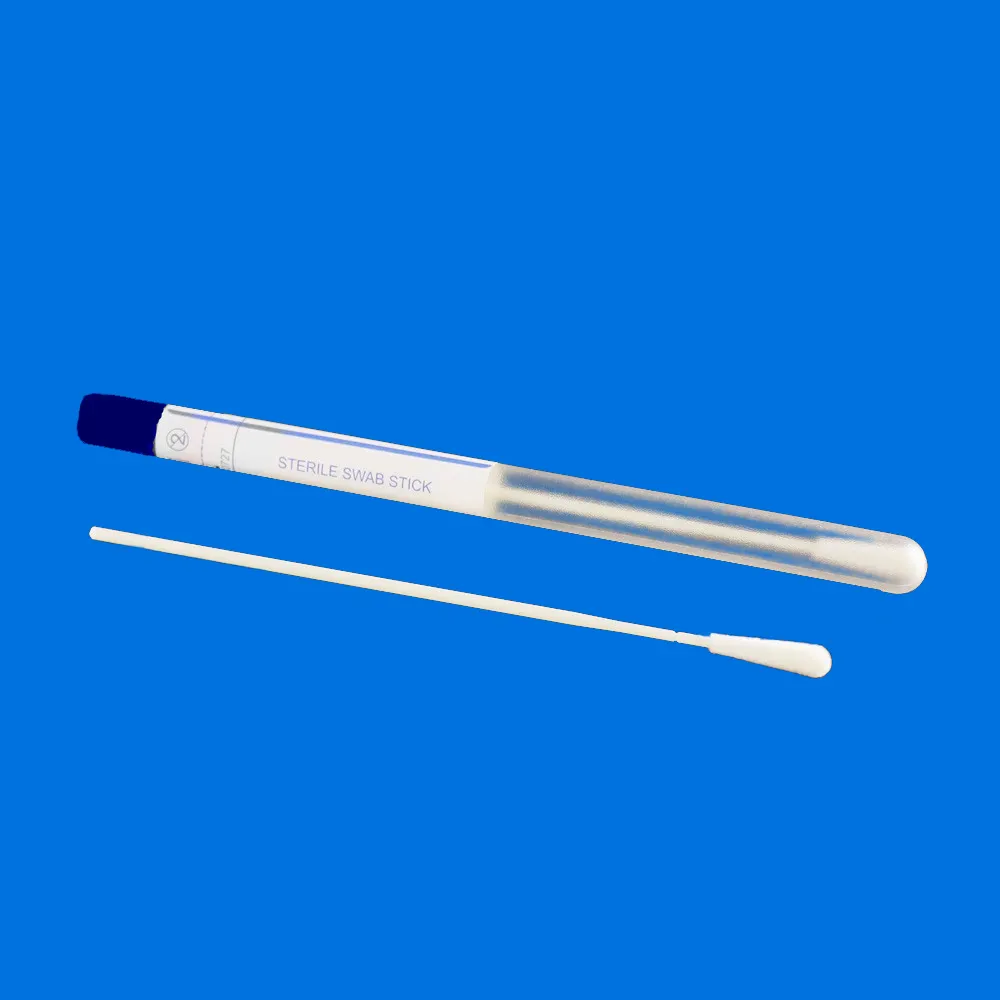

Cleanmo's flocked swabs feature perpendicular nylon fibers that optimize specimen collection and elution into transport media. The swabs also feature a molded break point that allows you to safely and easily break off the swabstick, and several break point options are available for different tubes. Unlike traditional fiber swabs, which resemble a mattress or cushion, Cleanmo's flocked swabs have no internal absorbent core to disperse and entrap the specimen. The entire sample stays close to the surface for fast and complete elution. The perpendicular Nylon fibers serve as a soft brush and allow improved collection of cell samples. Capillary action between the fiber strands facilitates strong hydraulic uptake of liquid sample, and the sample stays close to the surface allowing easy elution.

What are Flocked Swabs?

Cleanmo's flocked swabs comprise of a solid molded plastic applicator shaft with a tip that can vary in size and shape. The tip of the applicator is coated with short Nylon fibers that are arranged in a perpendicular fashion. This perpendicular arrangement results from a process called flocking, where the fibers are sprayed onto the tip of the swab, while it is held in an electrostatic field. The process creates a highly absorbent thin layer with an open structure.

Traditionally, compact fibers such as cotton, polyester, and rayon have been used to create swab tips. The fibers are compressed and shaped into the desired tip type.

These fibers still have many useful applications today. But it's estimated that only 10%–15% of the organisms collected on traditional spun fiber swabs can be recovered from cultures. The nature of spun fiber means entrapment of the specimen.

With particularly small samples, this could mean losing virtually all usable specimen, prohibiting subsequent sample analysis. The construction and shape of the swab are also important as these affect the amount of specimens recovered.

The ideal collection device must have the ability to absorb and release the sample and maintain the viability. This brings us to flocked swabs

The swab must come in contact with the posterior

nasopharynx mucosa and be rotated several times over 5-10 seconds to collect sufficient cells.

Proprietary flock processing maximizes collection and elution.

Molded Break Point

The handle has molded break point to prevent contamination

Polypropylene Handle

No adhesive residue, or fiber treatments to interfere with collection

Frosted tail of swab handle

It helps to easily hold the handle

| Part NO. | head

material | head

width | head

thickness | head

length | handle

material | handle

width | handle

length | total length | packing |

CM-FS913 | Nylon fiber

| 2.6mm

| 3.0mm

| 20.0mm

| ABS | 2.5 mm

| 127.0mm

| 147.0mm

| 100 swabs / bag

5000 swabs / ctn |

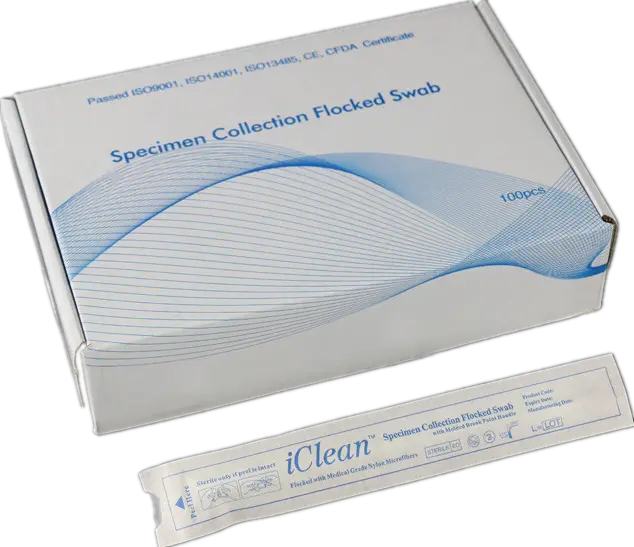

❈ Packing

The package bag or box can be designed as your requirements

Company Features1. Latest technology has been applied to the production of flocked swab .

2. We are committed to tackling the challenges of climate change in our own manufacturing operations and working with customers to improve social and environmental sustainability. Call!