Foam Cleaning Swabs: Why They're Ideal for Precision Cleaning

Foam Cleaning Swabs: Why They're Ideal for Precision Cleaning

Introduction

Cleaning delicate and hard-to-reach areas with utmost precision is a challenge that many industries face regularly. From electronics manufacturing to medical device assembly, the need for effective cleaning tools is paramount. Enter foam cleaning swabs – an indispensable tool for precision cleaning. In this article, we will explore why foam cleaning swabs are the ideal choice for industries that require meticulous cleanliness.

1. The Importance of Precision Cleaning

Without proper cleaning procedures in place, contaminants such as dust, dirt, oils, and residues can accumulate on sensitive surfaces. In industries like electronics manufacturing, these contaminants can cause malfunctions, decrease product quality, and even lead to complete device failure. Similarly, in the medical field, subpar cleaning practices can compromise patient safety and result in the spread of infections. Precision cleaning is vital for maintaining the performance, reliability, and safety of various products and environments.

2. The Versatility of Foam Cleaning Swabs

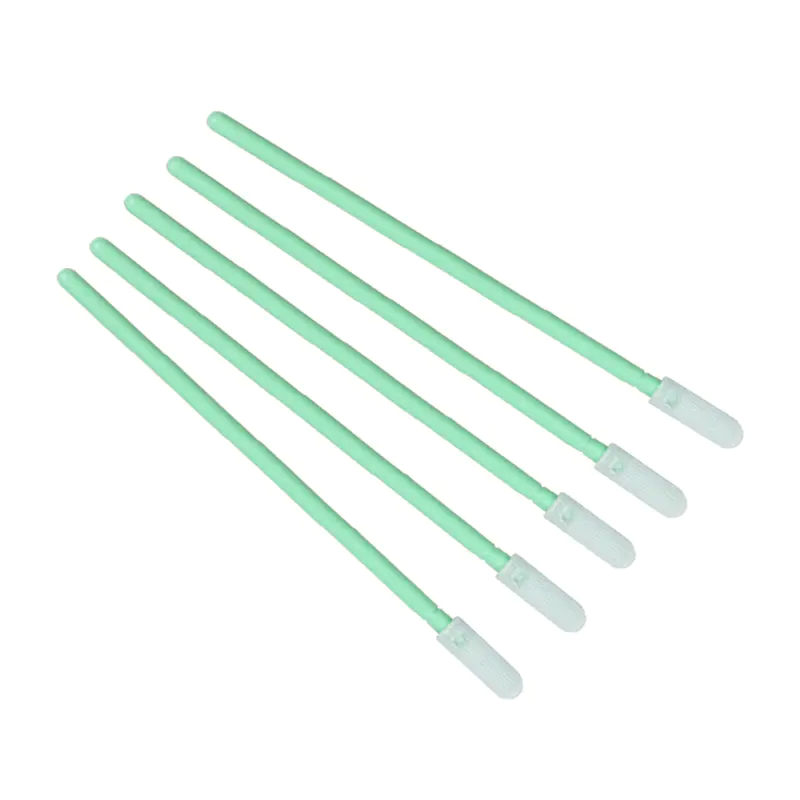

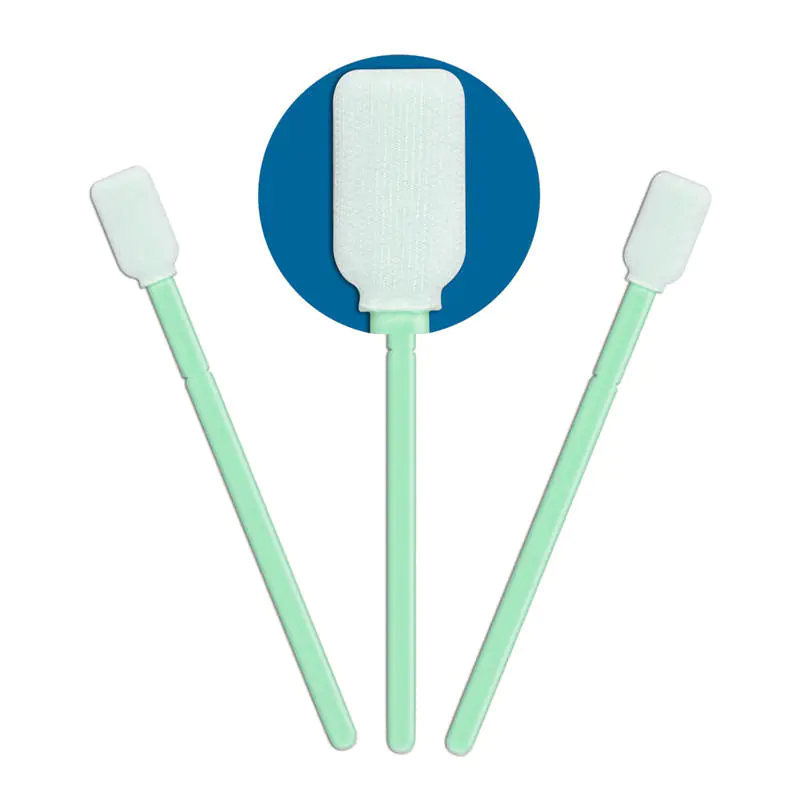

Foam cleaning swabs are uniquely designed to tackle precision cleaning tasks. Their flexible foam tips allow for effective removal of contaminants from delicate and intricate components. These swabs are available in a variety of sizes, shapes, and materials, making them suitable for different applications. Whether you need to clean optical lenses, printer heads, circuit boards, or medical instruments, foam cleaning swabs offer the versatility required for precise and reliable cleaning.

3. Excellent Absorbency and Retention

One of the key advantages of foam cleaning swabs is their excellent absorbency. The open-cell structure of the foam absorbs and retains a substantial amount of cleaning solvents or solutions. This property ensures thorough cleaning and prevents the transfer of contaminants from one surface to another. With foam cleaning swabs, you can achieve optimal cleanliness without leaving any residue behind, even in hard-to-reach areas.

4. Non-Abrasive and Lint-Free Cleaning

When it comes to precision cleaning, using abrasive or lint-producing materials is out of the question. Foam cleaning swabs are designed with these requirements in mind. The foam material used in these swabs is non-abrasive, allowing for gentle and safe cleaning of delicate surfaces without causing scratches or damage. Furthermore, the foam construction ensures that the swabs do not shed lint or fibers, eliminating the risk of leaving behind unwanted particles that could compromise the integrity of sensitive components.

5. Easy Handling and Ergonomic Design

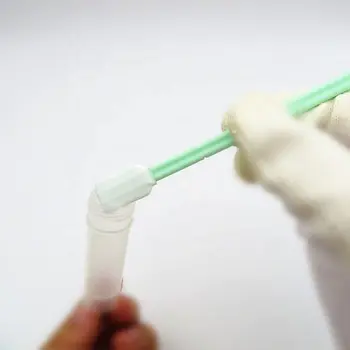

Foam cleaning swabs feature an ergonomic design that facilitates easy handling and maneuverability. Most swabs come with a sturdy handle that provides a comfortable grip, allowing users to apply the necessary pressure with precision. Additionally, the flexible foam tip conforms to various surface shapes, making it easier to access hard-to-reach areas. This combination of ease of use and ergonomic design ensures that cleaning tasks can be performed efficiently and without causing unnecessary fatigue.

Conclusion

In industries that demand precision cleaning, foam cleaning swabs play a crucial role. Their versatility, absorbency, non-abrasive nature, and lint-free cleaning properties make them the ideal choice for cleaning delicate and hard-to-reach surfaces. Whether you are a manufacturer in the electronics industry or a healthcare professional, employing foam cleaning swabs will help you maintain optimal cleanliness standards. Invest in these specialized cleaning tools and enjoy the advantages of their practicality, precision, and reliability in your cleaning processes.

Español

Español  Deutsch

Deutsch  Français

Français