Texwipe Swabs: Enhancing Safety and Efficiency in Cleanrooms

Enhancing Safety and Efficiency in Cleanrooms: Texwipe Swabs

Introduction

Cleanrooms play a crucial role in industries such as pharmaceuticals, medical devices, and electronics manufacturing. Maintaining cleanliness and sterility is of utmost importance to ensure product quality and safety. Texwipe, a leading provider of contamination control solutions, offers a range of innovative swabs specifically designed for cleanroom environments. These Texwipe swabs not only enhance safety but also optimize efficiency within cleanrooms. In this article, we will explore the features, benefits, and applications of Texwipe swabs, as well as their contribution to maintaining a pristine cleanroom environment.

I. The Importance of Cleanrooms in Various Industries

Cleanrooms play a critical role in industries where contamination can have dire consequences. In pharmaceutical manufacturing, for example, a contaminated environment can lead to compromised drug efficacy, affecting patient safety and ultimately harming the reputation of pharmaceutical companies. Similarly, in the electronics industry, even a tiny particle can disrupt the delicate circuits of electronic components, causing failures and malfunctions.

II. Understanding the Challenges in Cleanroom Environments

Cleanrooms face unique challenges when it comes to maintaining cleanliness. These challenges include:

1. Particulate Contamination: Controlling the presence of particles is crucial in cleanrooms. Even minuscule particles can interfere with sensitive processes or contaminate products.

2. Surface Contamination: Cleanroom surfaces must remain free of contaminants to prevent cross-contamination between products or to ensure proper functioning of equipment.

3. Sterility Maintenance: Some industries demand sterile environments, where the absence of microorganisms is essential. Achieving and maintaining sterility can be a challenge without effective contamination control products.

III. Introducing Texwipe Swabs: A Solution for Cleanroom Challenges

Texwipe, with decades of experience in contamination control, offers a range of swabs specifically engineered for cleanroom environments. These Texwipe swabs are designed to address the challenges mentioned earlier and provide a comprehensive solution for cleanliness and sterility needs.

IV. Features and Benefits of Texwipe Swabs

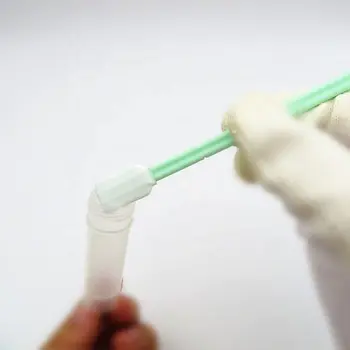

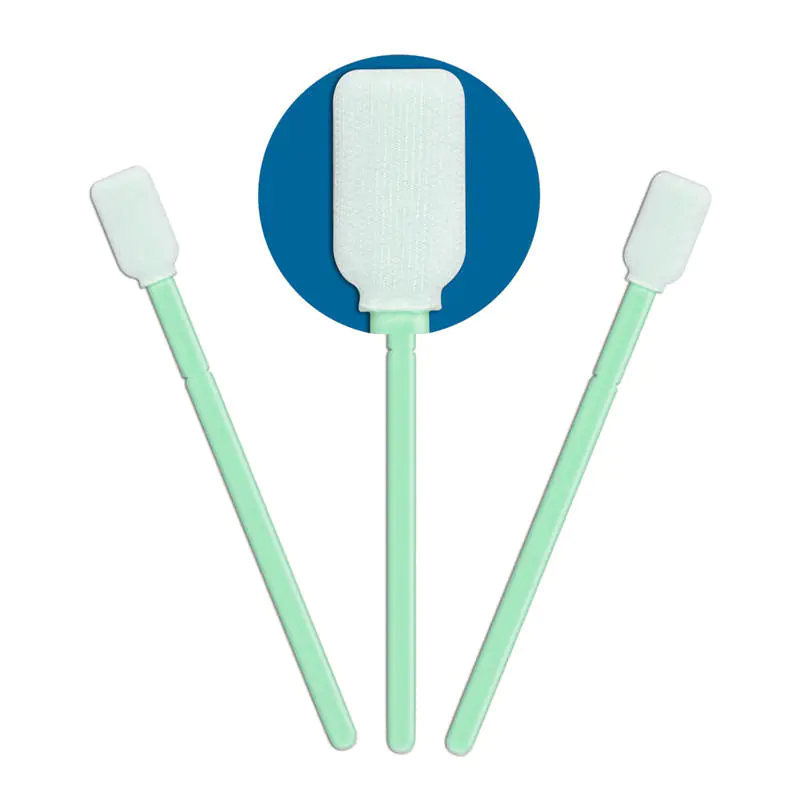

1. Precision Engineered Tip Design:

Texwipe swabs feature precision-engineered tips that are designed to effectively trap and remove contaminants. The data-driven design ensures optimal contact with surfaces, maximizing cleaning efficiency.

2. Low Particulate Shedding:

Texwipe swabs are manufactured using advanced materials and processes that minimize particulate shedding during use. This helps to maintain a cleaner environment and reduces the risk of particle contamination.

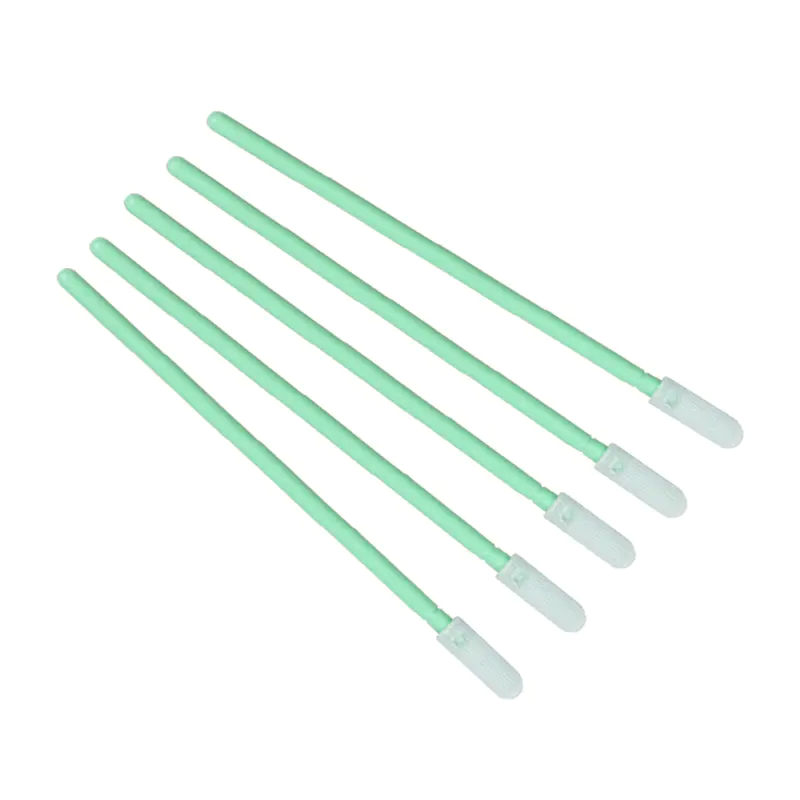

3. Variety of Swab Types:

Texwipe offers a wide range of swab types, including foam, polyester, and microfiber swabs, to cater to the diverse needs of different industries. This variety ensures that cleanrooms can select the most suitable swab for their specific applications.

4. High Absorbency and Solvent Compatibility:

Texwipe swabs are highly absorbent, allowing for effective and efficient cleaning or sampling actions. Additionally, Texwipe swabs are compatible with various cleaning solvents, ensuring versatility and suitability for a wide array of purposes.

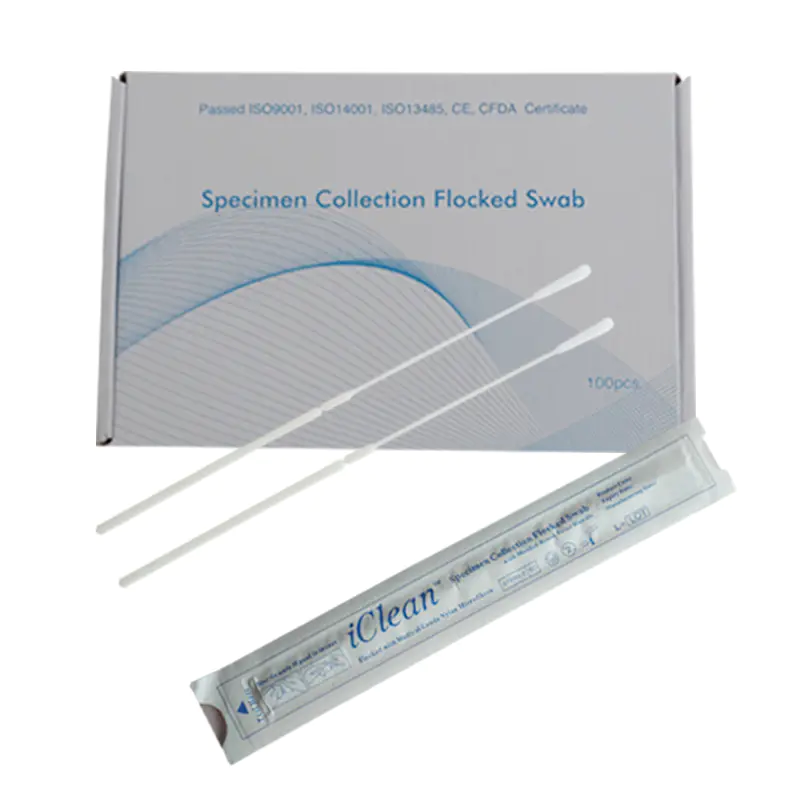

5. Validated Sterility:

In industries where sterility is critical, Texwipe provides swabs that are validated and certified as sterile. This gives users confidence that their cleanroom processes are not compromised by microbial contamination.

V. Applications of Texwipe Swabs in Cleanrooms

Texwipe swabs find applications in various industries, including:

1. Electronics Manufacturing:

In the electronics industry, Texwipe swabs are used to clean delicate electronic components, ensuring the elimination of dust, oils, and other contaminants that could compromise functionality.

2. Pharmaceutical Manufacturing:

In pharmaceutical cleanrooms, Texwipe swabs are utilized to sample surfaces and equipment to ensure a sanitary environment, free from microbial contaminants.

3. Medical Device Manufacturing:

Cleanliness is of utmost importance in the production of medical devices. Texwipe swabs offer a reliable solution for ensuring that devices are free from particles, oils, and other contaminants that may affect their performance or the safety of patients.

4. Aerospace and Automotive Industries:

In aerospace and automotive manufacturing, Texwipe swabs are employed to clean critical surfaces, removing particles, residues, and oils that could compromise precision instruments or affect the functionality of mechanical components.

5. Optics and Laser Industry:

The optics and laser industry require immaculate surfaces for high precision devices. Texwipe swabs ensure that optics are clean and free from contaminants that may interfere with transmission or beam quality.

VI. Conclusion

Maintaining cleanliness and sterility in cleanroom environments is essential across multiple industries. Texwipe swabs prove to be reliable, efficient, and safe tools for contamination control. With their precision design, low particulate shedding, and versatility, Texwipe swabs contribute to enhancing safety and efficiency within cleanrooms. Whether used in electronics, pharmaceuticals, medical devices, aerospace, automotive, or optics industries, Texwipe swabs offer a reliable and effective solution to maintain cleanliness and achieve optimal results in cleanroom environments.